Precision Composite Curing Ovens for Industrial and R&D Applications

High-performance composite curing ovens by UAVOS Inc. for curing, post-curing, and heat processing of composites, prepregs, thermoplastics, and tooling. Precision PID control, vacuum ports, and energy-efficient design for industrial and R&D applications

PRODUCT OVERVIEW

High-Performance Composite Heat Processing Solutions

UAVOS Inc. manufactures high-performance composite curing ovens engineered to the highest industrial standards. Designed for continuous operation at 200°C, these professional ovens deliver unmatched accuracy, efficiency, and durability for the most demanding composite material processing applications.

As standard, our Composite Curing Oven range features:

- Heavy-duty stainless steel interior for maximum durability;

- Increased temperature accuracy with rapid response;

- High thermal efficiency using thermally isolated steel panels with a ceramic fiber-insulated core;

- Touchscreen control system with intuitive programming for industrial oven operations.

Our ovens are specifically designed for composite manufacturing, including curing and post-curing of laminates, prepregs, thermoplastics, castings, and molds.

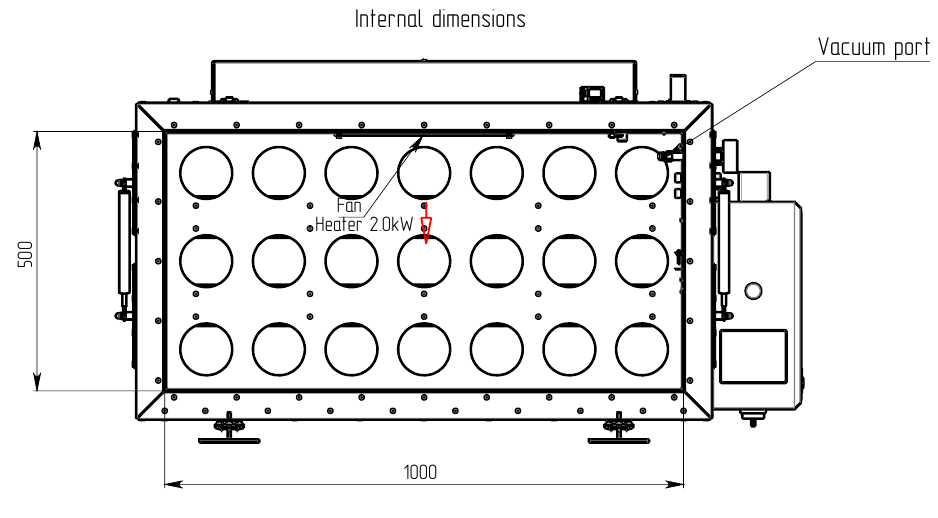

TOP-LOADING OVENS MODEL SPECIFICATIONS

| Model | Internal volume, L | Fan heating element, power, kW | Maximum power consumption, W | Total weight, kg | Internal dimension (D×H×W), mm | Outside dimension (D×H×W), mm | Installation space (W×H×D), mm | Price, USD, EXW |

|---|---|---|---|---|---|---|---|---|

| OVEN-500-1000 | 250 | 2 | 2400 | 130 | 500×500×1000 | 778×810×1325 | 2300×3000×2300 | 10 100 |

| OVEN-500-1500 | 375 | 4 | 4400 | 165 | 500×500×1500 | 778×810×1825 | 2800×3000×2300 | 11 100 |

| OVEN-500-2000 | 500 | 4 | 4400 | 210 | 500×500×2000 | 778×810×2325 | 3300×3000×2300 | 12 100 |

| OVEN-500-4000 | 1000 | 8 | 8800 | 390 | 500×500×4000 | 778×810×4325 | 5300×3000×2300 | 20 200 |

| OVEN-700-1000 | 490 | 2 | 2200 | 180 | 700×700×1000 | 978×1010×1325 | 2300×3000×2300 | 11 000 |

| OVEN-700-1500 | 735 | 4 | 4400 | 220 | 700×700×1500 | 978×1010×1825 | 2800×3000×2300 | 12 100 |

| OVEN-700-2000 | 980 | 4 | 4400 | 275 | 700×700×2000 | 978×1010×2325 | 3300×3000×2300 | 13 100 |

| OVEN-700-4000 | 1960 | 8 | 8800 | 520 | 700×700×4000 | 978×1010×4325 | 5300×3000×2300 | 21 200 |

| Technical Specifications | |

|---|---|

| Model | OVEN-500-1000 |

| Internal volume, L | 250 |

| Fan heating element, power, kW | 2 |

| Maximum power consumption, W | 2400 |

| Total weight, kg | 130 |

| Internal dimension (D×H×W), mm | 500×500×1000 |

| Outside dimension (D×H×W), mm | 778×810×1325 |

| Installation space (W×H×D), mm | 2300×3000×2300 |

Download Manual & Docs

INDUSTRIAL CURING OVEN FEATURES & SPECIFICATIONS

- Precision PID temperature control.

- Integrated overheat protection system.

- Programmable ramp and soak cycles.

- Standard mode and 19 pre-programmed settings.

- Two independent vacuum ports for vacuum-assisted curing.

- Rugged, production-ready build.

- Touchscreen controller with live temperature graphing.

- High energy efficiency for reduced operational costs.

Certified Quality

Our composite curing ovens are CE marked, ensuring compliance with the essential health, safety, and environmental requirements of the European Union. This CE marking demonstrates that our equipment meets the international standards for reliability and safety.

Engineered and manufactured in-house by UAVOS Inc., these ovens deliver reliable, repeatable, and precise curing for composite manufacturing, research, and development.

Advanced PID Temperature Control and Programming

Our curing ovens offer precise PID temperature control, featuring calibrated thermocouples and fan-assisted airflow to minimize stratification.

All curing parameters — including temperature, ramp rate, and soak time— are fully programmable, allowing users to store and run optimized cycles for different materials with ultimate precision and consistency.

Applications: Prepreg, Thermoplastics, and Tooling

Recommended for Aerospace, Automotive, and Marine Composites

- Curing of prepreg composite parts.

- Post-curing of high-temperature tooling and molds.

- Processing thermoplastics such as PP and PLA.

- Silicone curing and resin casting.

- R&D and materials testing for composite development.

Touchscreen Controller with 19 Custom Programs

- Developed by UAVOS Inc.

- 19 customizable programs + standard mode.

- Onscreen temperature graph overlays for real-time monitoring.

- Intuitive program creation for complex ramp and dwell cycles.

Vacuum-Assisted Curing for Precision Results

- Two integral ports with optional gauge and valve assemblies.

- Supports one or two independent vacuum lines.

SHIPPING&DATASHEETS

Worldwide Shipping & Quality Assurance by UAVOS Inc.

- Designed for worldwide shipping.

- Securely mounted to pallets for transport.

- Forklift or a tail-lift may be required for unloading.

Safety Guidelines and Technical Datasheets

UAVOS Inc. is not responsible for product misuse or failure to follow safety guidelines. Always consult the provided technical and safety data sheets before use.